Concrete is one of the most essential materials in modern construction, used in everything from residential buildings to massive infrastructure projects. Understanding its properties before it sets is crucial to ensure safety, durability, and strength. One of the most common methods to assess the quality of fresh concrete is the slump test. Many construction professionals and students ask the question: what is concrete slump? In simple terms, it is a measure of the consistency and workability of fresh concrete, providing insight into how easily it can be mixed, placed, and compacted. This article will explore the concept in detail, explain the procedure, its importance, factors affecting it, and common applications in the construction industry.

Understanding Concrete Workability

Concrete workability refers to how easily concrete can be mixed, transported, placed, and compacted without segregation or loss of uniformity. This property is closely linked to concrete slump, as slump testing is the most direct method to measure workability. A concrete mix that is too stiff may be challenging to place and compact, leading to honeycombing or weak spots in the finished structure. On the other hand, overly wet concrete can cause segregation and reduce structural strength. Knowing what is concrete slump helps engineers and construction professionals adjust the mix proportions to achieve the desired workability and performance.

The Concept of Concrete Slump

Concrete slump is defined as the vertical settlement of fresh concrete after it is removed from a standard cone mold. The measurement reflects the fluidity and workability of the mix. When concrete is poured into the cone and the mold is lifted, the concrete may settle or slump to a certain height. The difference in height between the top of the mold and the top of the slumped concrete is recorded as the slump. This simple measurement provides valuable information about the concrete’s consistency and whether it meets the required standards for a specific project. Understanding what is concrete slump ensures that concrete placed on-site performs as expected.

Importance of Slump Testing in Construction

Slump testing plays a critical role in quality control during construction. By performing the test, engineers can verify that each batch of concrete has the correct workability and water content. This helps maintain consistency across large projects, preventing weak spots and ensuring structural integrity. Slump testing is especially important for projects with heavily reinforced structures, precast concrete, or complex formwork where concrete must flow easily around obstacles. By understanding what is concrete slump, construction teams can identify issues before the concrete hardens, saving time and reducing costly mistakes.

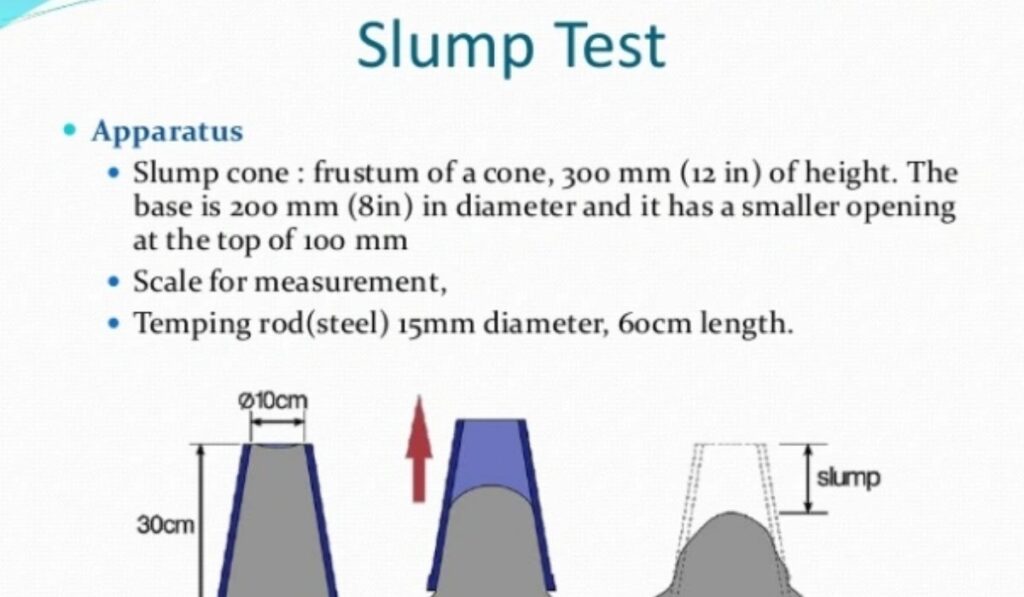

Equipment and Procedure for Slump Test

The slump test requires minimal equipment, making it convenient for both field and laboratory testing. The main tools include a standard slump cone, a flat base plate, and a tamping rod. The cone is filled with fresh concrete in three layers, each of which is tamped 25 times to remove trapped air. After filling, the cone is carefully lifted vertically, and the resulting slump is measured. Depending on how the concrete behaves, the slump can be classified as true slump, shear slump, or collapse slump. Understanding what is concrete slump ensures that the test is performed accurately and results are reliable for quality assessment.

Types of Concrete Slump

Concrete slump is categorized into three types based on the behavior of the concrete during the test. A true slump occurs when the concrete subsides evenly while maintaining its general shape, which is ideal for most construction applications. A shear slump happens when one side of the concrete slips, often indicating instability or uneven water distribution. Collapse slump occurs when the concrete falls apart completely, signaling that the mix is too wet. Knowing what is concrete slump and its types helps engineers interpret test results accurately and make necessary adjustments to the concrete mix.

Factors Affecting Concrete Slump

Several factors influence concrete slump, including the water-cement ratio, aggregate type and size, admixtures, and environmental conditions. A higher water content increases slump and improves workability but can reduce strength if not carefully controlled. Rounded aggregates typically allow higher slump compared to angular ones, as they reduce internal friction. Admixtures like plasticizers and superplasticizers increase slump without adding water, improving workability without compromising strength. Temperature and humidity also affect slump by changing water evaporation rates. Understanding what is concrete slump and these influencing factors is essential for producing consistent and durable concrete.

Applications of Slump Testing

The slump test is widely used in various construction scenarios to ensure concrete quality and workability. In building construction, it confirms that concrete can be placed efficiently in beams, columns, and slabs. For roads and pavements, slump testing helps maintain consistent surface quality and prevents weak spots. Precast concrete manufacturers use the test to ensure uniformity across factory-produced components. In large-scale projects such as bridges and dams, slump testing is crucial to confirm that concrete can flow into dense reinforcement areas without segregation. Knowing what is concrete slump and applying it correctly improves the safety and performance of these structures.

Advantages and Limitations of Slump Test

The concrete slump test offers several advantages. It is simple, quick, and requires minimal equipment, making it ideal for field use. It provides immediate feedback on the consistency of fresh concrete and allows for adjustments before the concrete hardens. The test also helps maintain quality across batches, preventing weak spots and ensuring structural reliability. However, the test has limitations. It only measures workability and does not indicate concrete strength, durability, or air content. Very dry or overly wet mixes may not provide reliable results. Understanding what is concrete slump and its limitations ensures that it is used appropriately alongside other quality control methods.

Best Practices for Accurate Slump Testing

Accurate slump testing requires proper procedure, what is concrete slump careful handling, and consistency in measurement. The base plate should be flat and non-absorbent, and the cone must be filled in three layers with uniform tamping. The cone should be lifted slowly and vertically to avoid disturbing the concrete. Recording the slump immediately ensures precise results. Regular calibration of equipment and training for personnel also contribute to reliability. Knowing what is concrete slump and following these best practices allows construction teams to maintain high standards and prevent costly errors in concrete placement.

Conclusion

Concrete slump is a simple yet vital measurement that provides insight into the workability and consistency of fresh concrete. Understanding what is concrete slump allows engineers, contractors, and construction workers to ensure that concrete mixes are suitable for specific applications, maintaining strength, durability, and safety. From building construction to infrastructure projects, slump testing remains an essential quality control tool. By performing the test correctly, interpreting results accurately, and considering influencing factors, construction teams can achieve consistent, reliable, and high-quality concrete for any project.

Frequently Asked Questions

1. What is the purpose of a concrete slump test?

- To assess the workability and consistency of fresh concrete.

2. Can slump testing be done on-site?

- Yes, it is designed for field testing with minimal equipment.

3. What does a low slump indicate?

- Concrete is stiff and less workable, suitable for heavy reinforcement.

4. What does a high slump indicate?

- Concrete is more fluid and easier to place but may have reduced strength if too wet.

5. Can admixtures affect concrete slump?

- Yes, admixtures like plasticizers can increase slump without adding water.